Automation

- Home

- Automation

Automation

BENEFITS OF AUTOMATION :

- Increased throughput or productivity Improved quality or increased predictability of quality

- Improved robustness (consistency), or processes or product

- Increased consistency of output

- Reduced direct human labor costs and expenses

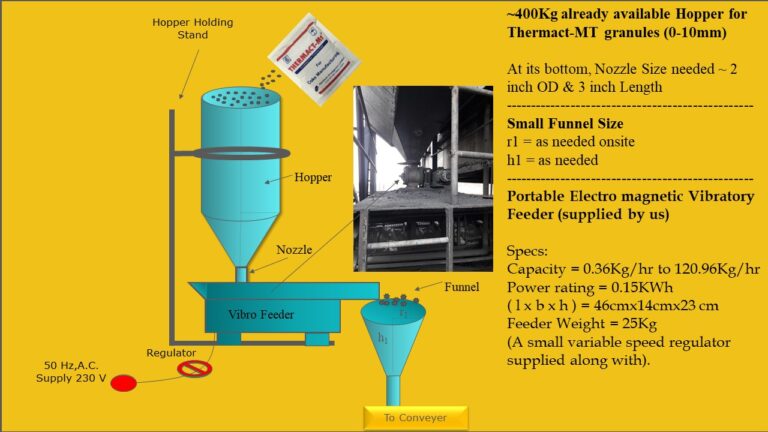

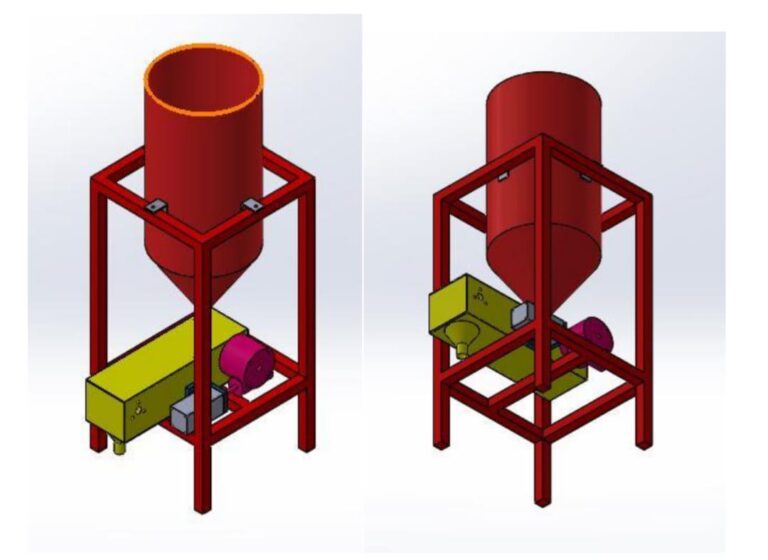

Tharmact Product dosing assembly

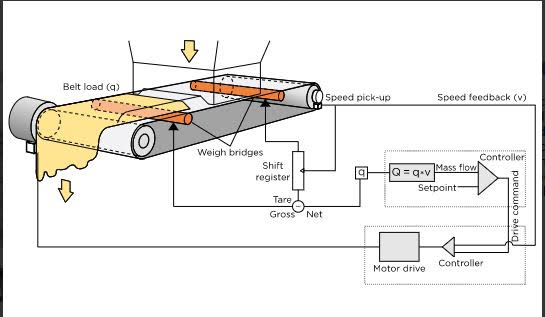

Weigh Belt Feeder :

It can be any number of material control devices that use a relatively short conveyor belt over which material passes and is at some point weighed through the belt. The weight belt feeder uses a load cell that measures the weight of a fixed-length section of the belt, yielding a figure of material weight per linear distance (mm) on the belt. A speed sensor (encoder) measures the speed of the belt. The product of these two variables is the mass flow rate of solid material “through” the weigh feeder:

W = Fv/d

W = Mass flow rate (Grams per minute)

F = Force of gravity acting on the weighed belt section (Grams)

v = Belt speed (mm per minute)

d = Length of weighed belt section (mm)

The continuous weigh belt controller, a closed-loop device, senses both weight and belt speed when calculating the actual feed rate. The controller compares the actual rate to the operator’s set rate and automatically adjusts belt speed as required. As per our calculation and design Feed rate of our equipment: 1gram/min to 500 gram/min and 500gram/min to 5000gram/min.

Accuracy :

The industry standard for weight feeders accuracy has been, Provides an accuracy of ±0.25 to ±1% of the set rate at ±2 sigma based on a minimum of 30 consecutive samples of one minute, 30 revolutions of the screw, or 1% of scale capacity, whichever is greater. Accuracy may vary depending on material flow characteristics. FEEDER CONTROL UNIT (Individual Feeder) Individual Feeder controller. 1. SIZE: 96x96x75 (External control box size not mentioned) 2. HMI: 2 x rows of 5 x digits, 6 x keys. 3. INPUTS: 1x load cell input (4 wires + shield), 1x encoder/proxi input for speed measurement. 4. OUTPUTS: 1x 0-10V output for speed control. 5. COMMUNICATION: 1 x RS485 port for communication over MODBUS with Master (2 wire/9600 bps). 6. SUPPLY: 24VDC, 1A MASTER UNIT: HMI Display, communication with MODBUS for Read, Wright and ongoing process display with max support of 6 individual feeder controllers.

- Advantages:

- Summary:

Paper plate making machine

- Paper Plate Size: 4″ To 18″.

- Paper Material: 80 gsm To 500 Gs

- Paper Plate: 4000 To 6000 Pcs. /HR.

- Thali: 1200 To 1800 Pcs/Hr.

- Bowl: 800 To 1000 Pcs/Hr.

- Power Source: 220 v-50 hz.-SINGLE Phase

- Electric Motor: 2 Hp – 1440 Rpm-

Single Phases – 230 v. - Weight Of Machine: 250 Kg. Approx.

- Fitted With Manual Operated Gear

- Oil Tank Capacity: 50 Ltr.

- 1 Hour Power Consumption With 2 Die Heater (1.5 To 2 Unit /HOUR) (1.5 To 2 Unit/Hour)

- Delivery Within 30 Days.

Tharmact Product dosing assembly

- Bottle Filling Machines

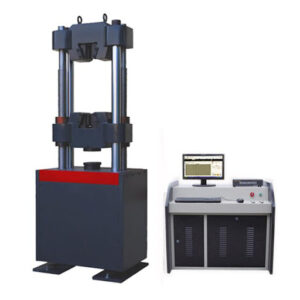

- Hydraulic Universal Testing Machines

- Semi – Automatic Compression Testing Machine

Pumping Unit: Dual Stage Hydraulic Pump submerged in oil and are housed manual pace rate controlling assembly & low-pressure pump for faster reduction of vertical daylight to apply the load quickly and also with low delivery & high-pressure pump for testing the specimen. Safety Feature: Provided with full view through Plexiglas, front safety door and rear is also covered with transparent material use to save user during incorporated with emergency switch to stop the machine

Our Similar Products

(High Capacity)

UNIVERSAL TESTING MACHINES

We have carved a niche amongst the most trusted names in this business, engaged in offering a comprehensive range of Universal Testing Machine.

(custom industrial equipment))

CONCRETE PERMEABILITY APPARATUS

The water permeability test on Concrete determines the resistance of concrete against water under hydrostatic pressure.

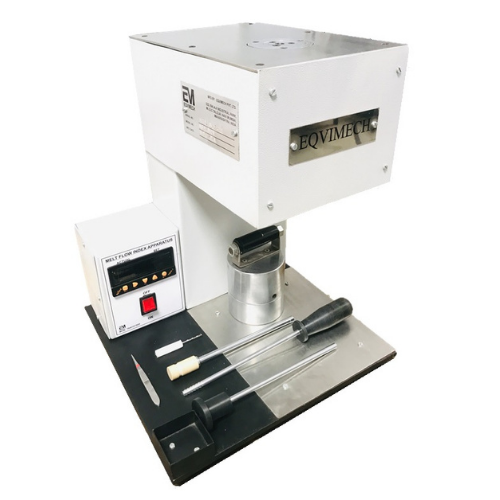

(Laboratory)

MFI (MELT FLOW INDEX)

Primarily used for goods inwards checks at plastics processing plants where extrusion tests are performed on an irregular basis.

Download Our Catalogs

Accordion Style 4

Accordion Title 1

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Accordion Title 2

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Accordion Title 3

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Accordion Style 4

Accordion Title 1

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Accordion Title 2

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Accordion Title 3

Some title here

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.