Muffle Furnace

- Home

- Muffle Furnace

Muffle Furnace

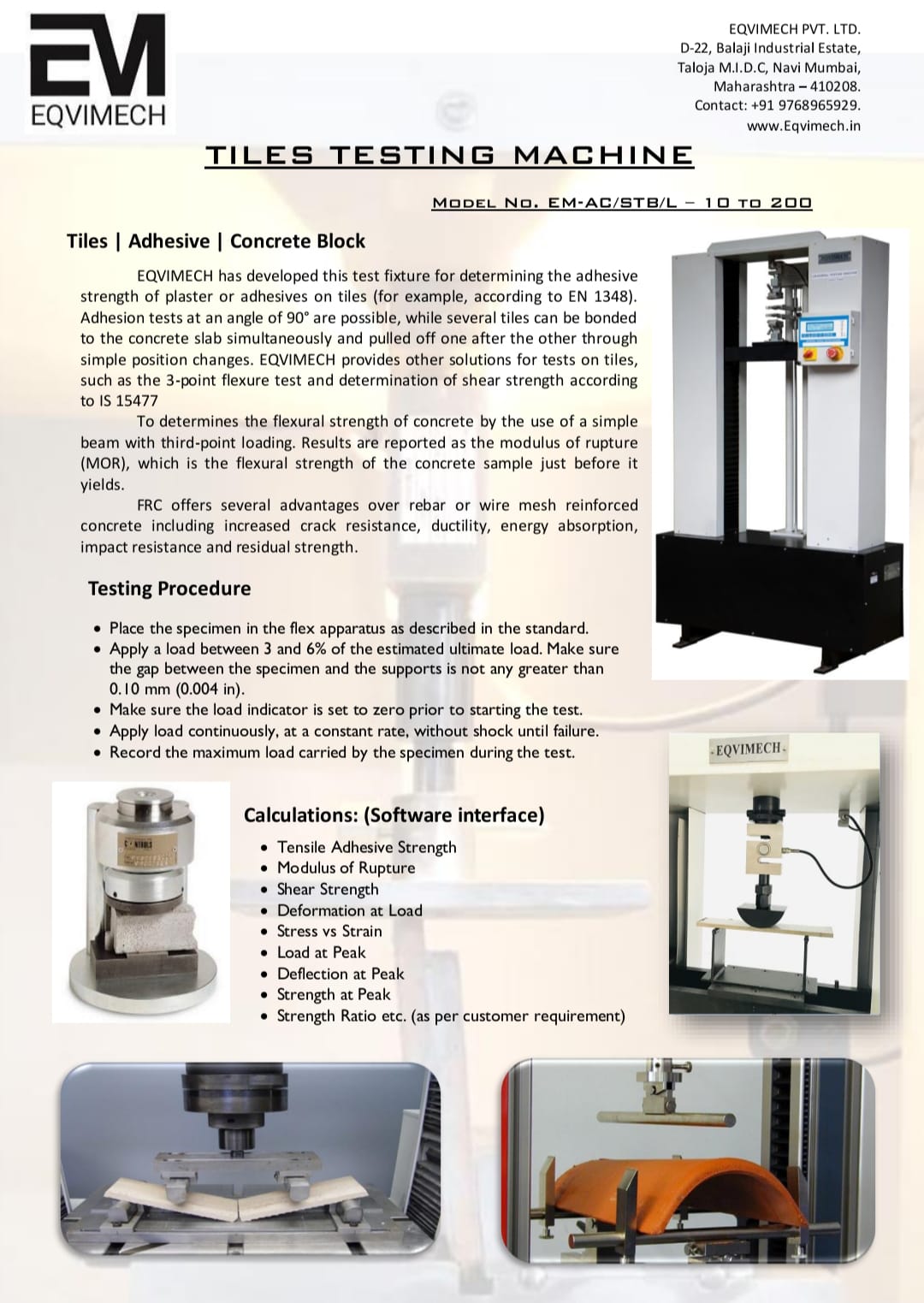

Muffle Furnace is box-type heat treatment equipment used to change the physical properties of samples at very high temperatures; for example, 1200°C. These laboratory furnaces are widely used in scientific experiments in the physics lab, rice laboratories, steel and paint industries, biotech companies and small industrial production, etc. Their major applications include general laboratory testing, annealing, ash determination, coal analysis, leaves carbonization, and lime calcination, etc. We are ISO and CE-certified muffle furnace manufacturers and suppliers in India. Our company makes these machines in various chamber sizes. Each unit is made with rugged construction and equipped with easy to use controller system and safety devices. Standard models of our muffle furnaces come with a maximum temperature range of 1200°C. Useful for hardening, annealing, preheating, etc. Lightweight high temp ceramic fiber wool insulation. Outer body thick P.C.R.C. sheet duly powder coated. Heating elements are of KANTHAL ‘A-1 Wire’. Two Pilot Lamps with Microprocessor-based Digital Temp Controller. & to work on 220/230 Volts AC. The max temp is 1200 ºC & working temp is 1130 ºC

| Size | Rating K.W. |

|---|---|

|

9”x4”x4”

|

1.6

|

|

10”x5”x5”

|

2.0

|

|

12”x6”x6”

|

3.5

|

|

18”x9”x9”

|

6.0

|

Description :

Abiding by the ethical norms of the industry, we have engaged in manufacturing, supplying, and exporting Pendulum Impact Testing Machine. Manufactured in accordance with industry laid guidelines, these impact testing machines are available in various specifications as well as in custom-built range to meet the needs of the customers. In addition to this, our professionals employ advanced machines and use quality approved material procured from the trusted vendors of the market.

- Longer functional life

- Least maintenance

- Assure minimum energy absorption during fracture

- Improved test accuracy

- Dimensional accuracy

- Robustness

- Suitable for Charpy and Izod impact test on various material

- Works on the pendulum principle

- Highly stressed and wearing parts such as support blocks and strikers made of alloy steels duly heat treated.

- Direct indication of impact energy absorbed by specimen on the large dial for models AIT-300-N, AIT-300-EN.

- Digital panel display for model AIT-300-D

- Equipped with safety guard for the operator

- Initial potential energy for Charpy is 300 Joules and for Izod is 170 Joules

- Least count of 2 Joules (for analog models) and resolution of 0.5 Joules (for digital model)

- The pendulum drop angle for Charpy is 140 Degree and for Izod is 90 Degree

- We also offer ASTM Impact testing machine manufactured in tandem with ASTM E-23 standard.

- Accuracy conforms to IS 3766-2003, IS 1598-1977, IS 1757-1999, IS 1499-2003, BS 131-Part I, II, III, IV, and BSEN-10045 -1993 (for Charpy).

Our Similar Products

(High Capacity)

UNIVERSAL TESTING MACHINES

We have carved a niche amongst the most trusted names in this business, engaged in offering a comprehensive range of Universal Testing Machine.

(custom industrial equipment))

CONCRETE PERMEABILITY APPARATUS

The water permeability test on Concrete determines the resistance of concrete against water under hydrostatic pressure.

(Laboratory)

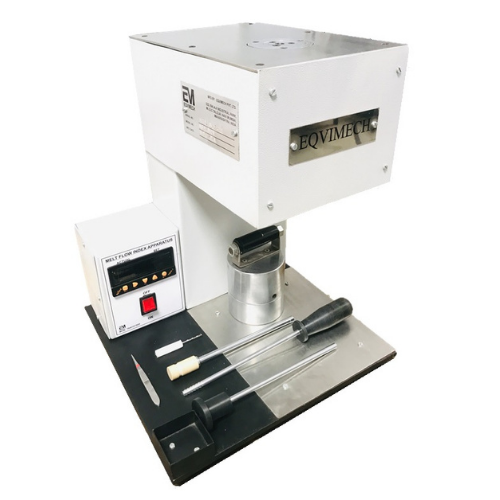

MFI (MELT FLOW INDEX)

Primarily used for goods inwards checks at plastics processing plants where extrusion tests are performed on an irregular basis.