Accessories

Accessories

- Home

- Extensometer

Contact Type Extensometer / Long travel Extensometer

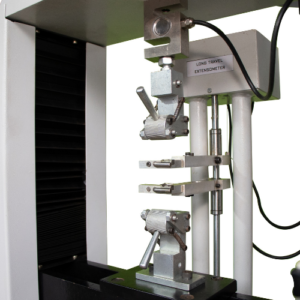

The need for companies to increase specimen throughput to maximize efficiency and revenue while maintaining high-quality standards and safe operating conditions has created a demand for increased speed, reliability, and accuracy in their material testing routines. It is an automated long-travel extensometer that fulfills this demand with sub-micron precision. With the benefit of automated gauge length positioning and attachment to the test specimen, operators enjoy a safer and simplified test routine. Companies gain faster cycle times and eliminate the variability of critical test results brought upon by manual, time-consuming steps of traditional clip-on extensometers

Principle of Operation

The Model integrates with EQVIMECH’s test systems and is controlled with Universal TM testing software via the USB interface. The software provides an easy-to-use test sequence and setup that facilitates the automated gauge length, reference arm position, and opening and closing of the arms before and after testing. The counterbalanced measuring arms are virtually weightless, thus removing any influence on the material properties under test. The measuring arms are motor-driven and will automatically position themselves to the correct position and gauge length every time.

Application Range

- Tensile testing: metals, composites, plastics, and elastomers

- Flexure testing: plastics

- Specimen shapes: strip, round, hexagonal, and flat

- Standard compliance: Conforms to the most rigorous testing standards, including:

- ISO 527-2 and ASTM D638 for plastics

- ISO 6892-1(Strain Control Method A1) and ASTM E8 (Strain Control Method B) for metals.

High Travel

With high accuracy and resolution across 800 mm of travel, the model encompasses a wide range of specimen sizes and gauge lengths to reduce test setup time and equipment inventory.

Counterbalance Technology

Tried and tested counterbalanced technology eliminates external influences on the material under test to produce highly repeatable and reliable test measurements.

Automated Test Arms

Designed to provide simplified and safer test routines, reduce cycle time, and high reproducibility. The automated arms attach to the specimen and can remain attached through failure for most materials.

Interchangeable Knife Edges

Swappable knife edges and adjustable clamping forces accommodate a variety of materials and specimen geometries.

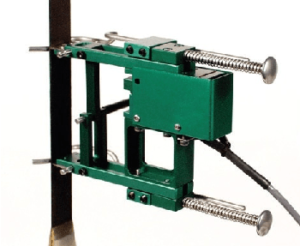

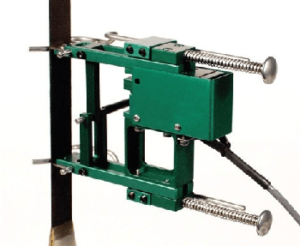

Designed for measurement of higher extensions on plastics, rubbers, elastomers, cellular plastics, thin sheeting, and films showing maximum forces higher than approximately 20 N. The special design of the gripper arms of the extensometer releases the specimen at break especially for testing of rubbers and elastomers showing a tendency to wrap around the sensor arms at failure.

Features & Specifications

- Gauge length adjustable from 15 mm to 50 mm

- Travel range Up to 800 mm

- Resolution 0.01mm (10 microns)

- Suitable for Elastomeric materials like polymers, rubbers, plastics & more.

Strain Gauge Type Extensometers

Extensometers measure strain, the change in length of a specimen divided by the original length (gauge length) of the specimen, by means of knife edges that contact the sample. Strain gauge clip-on extensometers are manual clip-on extensometers, that are clamped to the specimen. With various preset gauge lengths they are suitable for use on metal and plastic specimens. Measuring systems possess excellent linearity, providing reliable test results. Lightweight, miniaturized construction, ideal for short specimens.

Advantages & features

- Excellent linearity for reliable test results.

- Variable measurement options are possible on extensometers with 2 separate measurement systems; individual signals or mean-value signal can be displayed.

- High resolutions enable the measurement of very small deformations during test.

- Lightweight, miniaturized construction, ideal for specimens with small parallel length.

- Initial gauge length can optionally be reset from 10 to up to 100 mm using extension pieces (does not apply to Type DMS Length 1).

- Extensometers for two-sided measurement of specimen deformation, enabling exact determination of Young’s modulus and engineering elastic limit.

- While attached to the specimen the extensometer is prevented by limit stops from exceeding the measurement travel and protected in the event of specimen break (Type DMS Length 1 only)