Accessories

Accessories

- Home

- Controller Interface Type

CONTROLLER INTERFACES -

Choose what suits your requirement

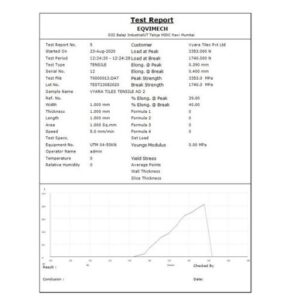

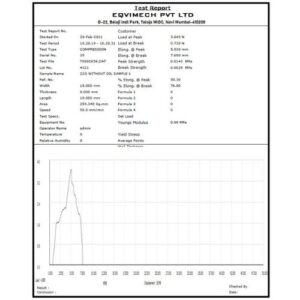

Our Computer software is a dedicated material Testing software from Eqvimech.

Live Graph/Carrying Out test operations/Graphical Representations of Load & Displacement/Tensile Strength/Breaking strength/Yiels stress/Load Vs Displacement/Load Vs Elongation/stress vs strain/Load vs Time/and more…

Machine control, data analysis, and reporting are performed for measurement to key standards.

Its easy-to-understand icons and workflows make it easy to train new or experienced users allowing you to start testing even faster than ever before.

Unbelievably True with Result in milliseconds Accuracy in microns & Result in satisfaction.

The visual presentation will give you remarkable experience

For more Visuals visit our YouTube

Our Computer software is a dedicated material Testing software from Eqvimech.

Live Graph/Carrying Out test operations/Graphical Representations of Load & Displacement/Tensile Strength/Breaking strength/Yiels stress/Load Vs Displacement/Load Vs Elongation/stress vs strain/Load vs Time/and more…

- Machine control, data analysis, and reporting are performed for measurement to key standards.

- Its easy-to-understand icons and workflows make it easy to train new or experienced users allowing you to start testing even faster than ever before.

- Unbelievably True with Result in milliseconds Accuracy in microns & Result in satisfaction.

- The visual presentation will give you remarkable experience.

- For more Visuals visit our YouTube

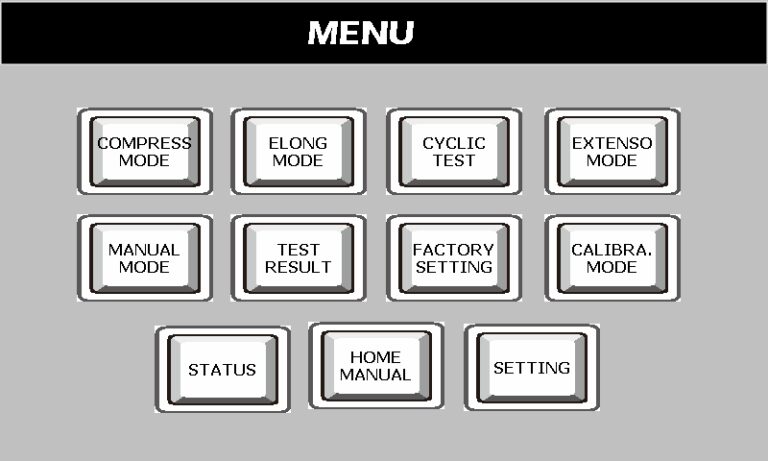

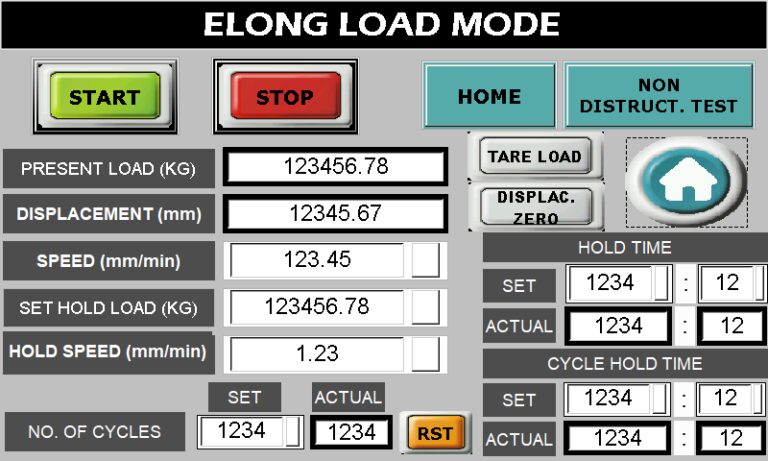

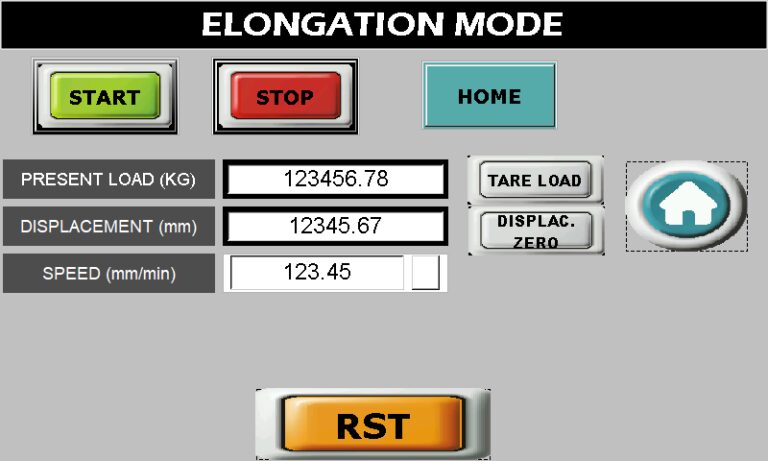

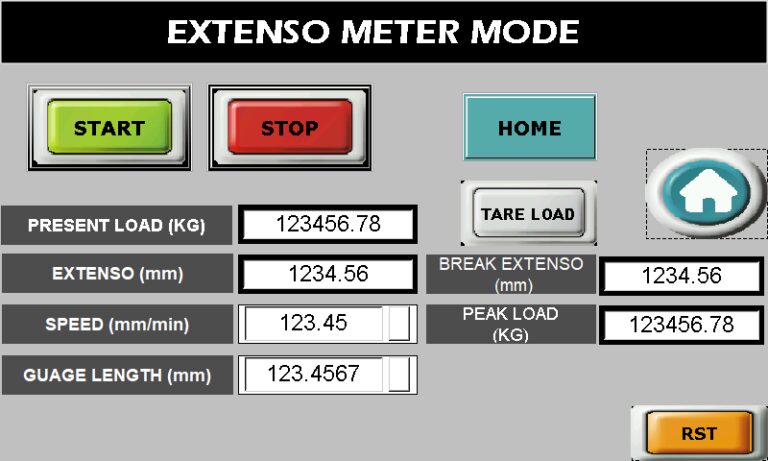

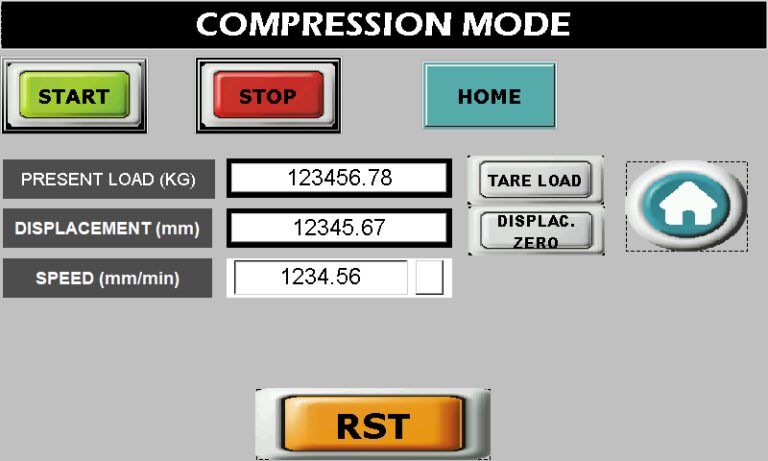

PLC CONTROLLER (TOUCH SCREEN)

PLC-based HMI control system is built from the user experience of engineers with touch interaction. The new portrait layout gives you a comprehensive view of the test workspace and allows you to start testing even faster than ever before.

- HMI display (Touch Screen Interface) of load and displacement.

- Front panel membrane type keyboard for test set up.

- Cyclic Test can be performed.

- Constant Loading with variable displacement and Vice versa.

- Storage of important parameters such as peak load, breaking load, and max.

- Facility to return of crosshead to the home position for next test.

- Overload & over travel protection is standard.

- Easy Load Cell selection option.

- Lower capacity load cells can be used with any machine for better load resolution and much more at just one touch.

- Well, It has everything you need for your quality assurance.

- HMI display (Touch Screen Interface) of load and displacement.

- Front panel membrane type keyboard for test set up.

- Cyclic Test can be performed.

- Constant Loading with variable displacement and Vice versa.

- Storage of important parameters such as peak load, breaking load, and max. displacement.

- Facility to return of crosshead to the home position for next test.

- Overload & over travel protection is standard.

- Easy Load Cell selection option.

- Lower capacity load cells can be used with any machine for better load resolution and much more at just one touch.

- Well, It has everything you need for your quality assurance.

LCD MICRO-CONTROLLER

Electronic control panel uses latest microprocessor which incorporates state of the art technology with following features.

UTM-G-310C is a microcontroller based tensile testing system, for load cell inputs, with digital display of the load and length. The load displayed for elongation or compression is in kg/ton or newton/kn. The length between the two jaws is displayed in mm. The calibration for the load cell is stored in the memory.

The UTM-G-310C unit, incorporates – a backlighted sixteen character by two line display for display of load applied on sample and the elongated/compressed length.

The unit UTM-G-310C incorporates membrane key switches. The operations that can be performed by the key switches are – start elongation test, start compression test, move the jaw to home position, stop the motor operation, change the motor speed if ac drive used, programming the unit of load (kg/ton or n/kn, manual movement of jaw either up or down, manual tare of the load, and view of the data for the previous test.

UTM-G-310C incorporates a high resolution ADC. The controller can be set for the load cell capacity to be used. Proper selection of the load cell being used is necessary. The load can be calibrated by keys. The resolution of the load is one count in ten thousand counts. The load cell selection can be done from the following load cells

Features:– Microcontroller-based intelligent unit.

- Both directions of motor movement – selection potential free output.

- Display the load as well as the elongation/compression length of the sample.

- Manual/Auto tare.

- Manual movement of the jaw either up or down.

- Load resolution – 1 count in 20 thousand counts – 0.005 %.

- Length resolution 0.01 mm on display. Actual resolution as per the encoder used.

- Limit sensors input for the upper and the lower limit of the jaw.

- Home key to bring the movable jaw back to the home position after the test is over for locking the next sample between the jaws.

- Non-volatile memory for data storage – related to the load and length programming.

- Calibration of load by keys. Calibration stored in non-volatile memory.

- Optional 4-20mA output for speed – if connected to AC drive.

- Optional RS232 interface output for a computer program.

- An optional computer program to store and generate test reports.

- Both directions of motor movement – selection potential free output.

- Display for the load as well as the elongation/compression length of the sample.

- Manual/Auto tare.

- Manual movement of the jaw either up or down.

- Load resolution – 1 count in 20 thousand counts – 0.005 %.

- Length resolution 0.01 mm on display. Actual resolution as per the encoder used.

- Limit sensors input for the upper and the lower limit of the jaw.

- Home key to bring the movable jaw back to the home position after the test is over for locking the next sample between the jaws.

- Non-volatile memory for data storage – related to the load and length programming

- Calibration of load by keys. Calibration stored in non-volatile memory.

- Optional 4-20mA output for speed – if connected to AC drive.

- Optional RS232 interface output for a computer program,

- An optional computer program to store and generate test reports.