MFI(Melt Flow Index)

- Home

- MFI

Previous

Next

MFI (Melt Flow Index)

MFI (Melt Flow Index)

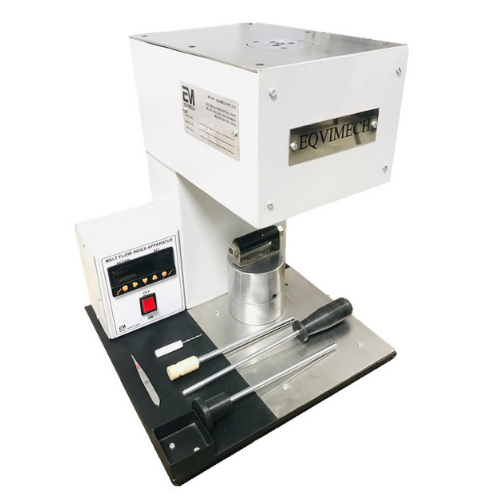

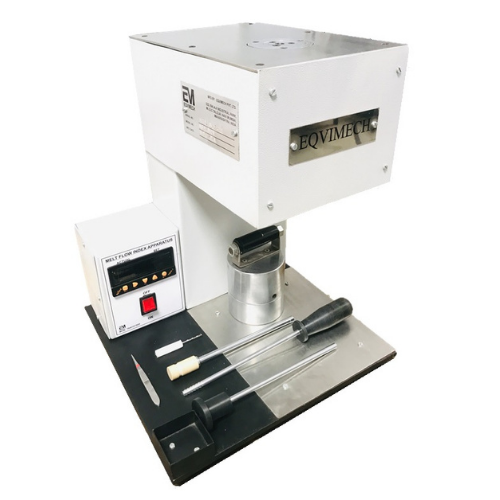

Primarily used for goods inwards checks at plastics processing plants where extrusion tests are performed on an irregular basis. The Table-Top Model with Manual & Automatic Cutting arrangement are designed as a stand-alone instrument for monitoring/verifying of Melt flow rate (MFR).

| Description | Value | Units |

|---|---|---|

|

Type

|

Melt flow extrusion (230 V)

|

|

|

Model No.

|

EM-M01 ( Manual Cutting of Sample ) EM-A02 ( Automatic Cutting of Sample )

|

|

|

Test load

|

0.325 to 21.6

|

kg

|

|

Dimensions

|

350 mm x 350 mm x 450 mm

|

|

|

Approx. weight

|

35

|

kg

|

|

Test temperature

|

120 to 400 Up to 450 when Customized

|

°C

|

|

Display

|

7-segment LED display (optional)

|

|

|

Temperature display resolution

|

±0.1

|

°C

|

|

Included in delivery:

|

Weights for load levels 2.84 kg and 2.16 kg

Cleaning accessories : Piston, barrel cleaner; Tungsten Carbide orifice, Barrel Cleaner; orifice Cleaner

|

|

|

Power supply

|

220 to 240 V | 1Ph

|

|

|

Power consumption (full load); approx

|

0.6

|

kVA

|

|

Power frequency

|

50

|

Hz

|

Description/Features:

- Quick Applications

- Advantages & Features

- Melt Flow Index is a compact instrument for rapid checking of the melt mass flow rate of plastics as per Method .

- It is primarily designed for plastics processors with a less frequent need for extrusion tests and no requirement for connection to a PC.

- Melt Flow Index is intended for MFR tests to Method A. Tests can be performed by the following standards:

- Method A&B as per ISO 1133, ASTM D1238.

- Live Temperature in the extrusion barrel is indicated on an LED display with the temperature sensor mounted on the barrel.

- The instrument can quickly be checked using the test granulate.

- Temperature control of the heating elements, heating chamber, and barrel are all perfectly coordinated. The temperature is generated at the location where it is utilized, ensuring excellent temperature distribution over the whole barrel height from the outset

- Simplified cleaning, with rapid expulsion of residual specimen material. – The orifice is located on the underside of the extrusion barrel. Removing the orifice from the barrel from the upwards direction, allowing it to be removed easily. – Expelling the die plus residual material after the test is similarly fast and easy. The barrel is now accessible throughout, simplifying cleaning.

- Equipment is calibrated for temperature mass, Orifice & barrel inner diameter.

- A comprehensive accessory range including automatic or manual extrudate cutter, separating pane, and die plug is optionally available

Our Similar Products

(High Capacity)

UNIVERSAL TESTING MACHINES

We have carved a niche amongst the most trusted names in this business, engaged in offering a comprehensive range of Universal Testing Machine.

(custom industrial equipment))

CONCRETE PERMEABILITY APPARATUS

The water permeability test on Concrete determines the resistance of concrete against water under hydrostatic pressure.

(Laboratory)

MFI (MELT FLOW INDEX)

Primarily used for goods inwards checks at plastics processing plants where extrusion tests are performed on an irregular basis.